Oilhub – Analytical System for Fuel and Machinery Cost Management

What Oilhub can do:

- Shows who refueled, when, and with what – data is taken directly from the refueling list and assigned to the employee.

- Checks if the person had scheduled work in SmartField – and whether they submitted a report.

- Verifies whether the operation of each loader complies with the plan created by the financial model.

- Automatically detects suspicious cases – e.g., refueling without work, work without refueling.

Oilhub is an integrated tool designed for precise control of fuel consumption and operating costs of vehicles on farms.

The application operates at the intersection of operational and financial data, providing full transparency and the ability to quickly verify any deviations.

What makes Oilhub unique?

Cross-system verification – anomaly detection

Oilhub not only collects data from external systems (SmartField, MFO, OMS), but also enables their cross-comparison. This allows you to quickly detect:

- Vehicles that have refueled with more fuel than the requirements defined in SmartField (for crop production),

- Exceedances of fuel consumption standards in animal production — by comparing actual consumption with calculations from the financial model (MFO),

- Budget overruns for spare parts and service — identified by linking invoices (OMS) with assigned costs and budget limits for each vehicle or machine.

Full automation and a consistent cost overview:

Oilhub automatically combines data from multiple sources into a single, coherent report that shows the complete cost flow – from invoice to budget and execution.

The system integrates data from:

- invoices (OMS) – with cost assigned to a specific machine or vehicle,

- financial budgets (MFO) – enabling automatic monitoring of budget overruns,

- SmartField – verifying whether the fuel and parts used correspond to the actual work performed.

Everything happens automatically

Data from different systems is consolidated into a single summary that clearly shows deviations and supports decision-making.

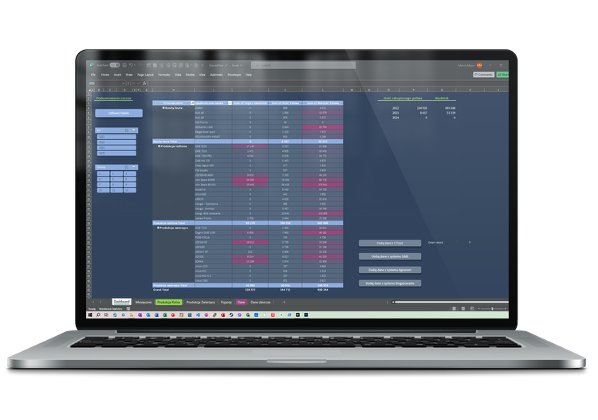

Fuel comparison: plan, execution, refueling

Oilhub integrates data from:

-

Cost invoices (OMS) – with specification of which machine or vehicle each part concerns,

-

Financial budgets (MFO) – to verify whether repair and purchase costs stay within the set limit,

- Three independent data sources on fuel consumption (SmartField + refueling):

- Planned fuel consumption value – derived from the work schedule in SmartField,

- Reported fuel value – calculated based on work actually performed and reported by machine operators (both planned and additional),

- Actual consumption – based on refueling data.

This makes it possible to precisely capture the differences between what was planned, what was actually performed, and what was physically refueled.

The system automatically points out deviations – whether due to work inefficiency, reporting errors, abuse, or equipment failures.

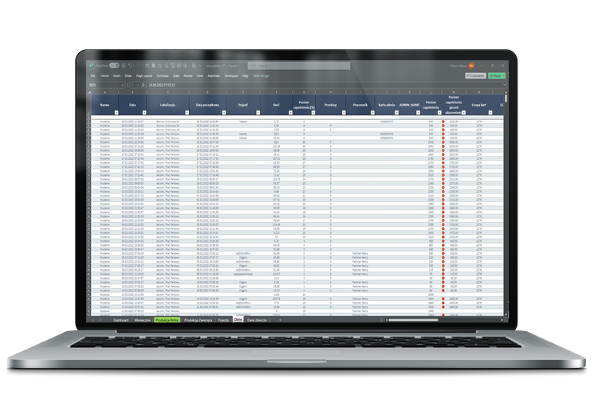

Oilhub automatically analyzes the cost of spare parts and service, comparing them with the budget and the actual utilization of machines.

The system retrieves data from invoices (OMS), assigning each item to a specific machine or vehicle. It then matches this information with:

- financial budgets from MFO – assigned to individual machines, types of parts, or service activities,

- service history and the intensity of vehicle use – making it possible to assess whether the cost is justified.

If any machine generates excessive costs (e.g., exceeding the spare parts budget or requiring service too frequently), Oilhub will immediately highlight this.

If any machine generates excessive costs (e.g., exceeds the spare parts budget or requires service too often), Oilhub will immediately highlight this.

The system allows for quick filtering by:

- machine, month, cost type,

- supplier, part category,

- status: within norm / budget exceeded.

This makes it possible to instantly identify which vehicles generate the highest costs, why this is happening, and whether there are any irregularities in cost assignments (e.g., invoice errors, accounting mistakes, excessive usage).

Automatic alerts and reports

The system highlights which vehicles exceed the budget in the selected period.

- Automation – minimal effort, maximum data for analysis

- Savings – quick identification of inefficiencies and losses.

- Alerts about deviations in refueling and parts costs.

- Transparency – every liter of fuel is accounted for

- Summary and detailed reports: comparison of plan/report/refueling, analysis of repair and parts costs.